OUR SERIES

LINEAR VPI

Our latest and constantly updated lineup of linear vibrators has now reached its best design ever combin-ing extremely low noise level to a compact and simple design.

Machined at the highest level of technology to ensure best-in-class longevity.

APPLICATIONS

- Compacting bulk materials

- Filling aid

- Mechanical processes excitations

- Moving material on conveyors

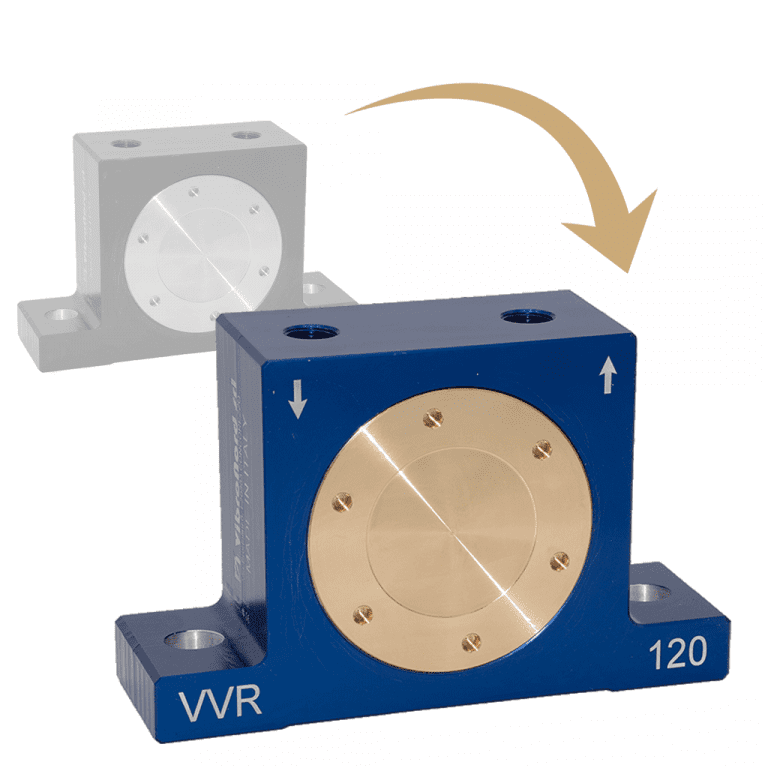

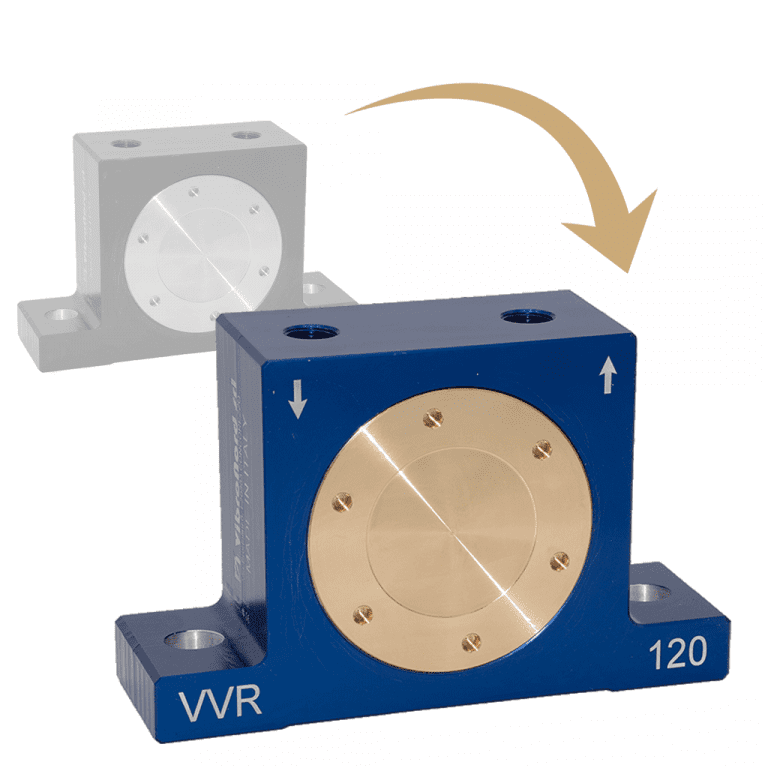

ROLLER VVR

Our roller pneumatic vibrators series features five sizes of devices to accomodate all the possible requirements in the Industry. Precisely machined to achieve the highest longevity, effectiveness and sound efficiency.

Our extremely refined machining and assembly procedures, combined with top quality materials as bronze, deliver an extroardinary longevity.

APPLICATIONS

- Emptying of hoppers and chutes

- Preventing adhesions in pipelines and silos

- Transporting of fine powders

- Compacting of plastic and concrete

- Conveying

BALL VVS

Our ball vibrators lineup features 8 devices able to deliver an economic but effective solution when generic vibration is required.

The particularly refined machining process allow our ball vibrators to last longer than average in the industry, providing a safe and constant vibration to the machine to which they are attached. Steel hardened tracks are machined to give the least friction surface to the sphere that rotates on them, delivering a low-noise vibration.

APPLICATIONS

- Emptying bunkers

- Preventing adhesion in pipelines

- Fine powders movement

- Moving of generic goods

IMPACT VPB

Our impact vibrators lineup features three device of different sizes to accommodate all the needs in the industry. Available both in galvanized and light blue.

A steel hardened piston excites the surface on which it impacts on. Our refined machining process ensure a long lasting industrial devic-es, used in a broad field of application, from food delivering to vision and industry 4.0 automation devices.

APPLICATIONS

- Food industry

- Preventing adhesion in silos

- Knocking material off

- Exciting objects when different positioning or orientation is needed

TURBINE VVT

VVTOur turbine pneumatic vibrators lineup features twelve devices to match all the possible applica-tions in the industry. This lineup is ideal when at the same pressure, high frequencies are required. In addition, turbine vibrators do not require lubricated air when functioning, which makes them the ideal choice in food industry application or when air with impurities cannot be discharged in the ambient.

The particularly refined machining process allow our turbine vibrators to last longer than average in the industry, providing a safe and constant vibration to the machine to which they are attached.

APPLICATIONS

- Food Industry

- Preventing adhesion in pipelines

- Fine powders movement

- Smooth surfaces

STAINLESS STEEL VTI

Our lineup of Stainless Steel Turbine Vibrators made of AISI 316L has been developed to respond to the demand of the sectors where it is needded to move items in sterile environments or when machineries are subject to frequent washings and cleanings.

The lineup is composed by four models to address the requirment of different size of machinery and material to move. From few grams to hundreds of kgs. They work extremely quietly and with dry air.

APPLICATIONS

- Food Industry – Pharmaceutical – Automation

- Prevention of adhesion to walls and surfaces

- Fine powders, pills and discrete items movement

- Compacting of grains and powders

Contact our experts!

We guide our customers to find the perfect product for the right application.

Contact us for support and customized offer.

.

Spare parts ready for you

All of our vibrators are a direct swap to the most popular brands of the sector.

Need a custom quotation? Contact us

Contact details

Via Giacomo Brodolini, 6

20863 Concorezzo (MB)

+390396800139

vibronord@vibronord.com

Mon - Fry: 7:30 -17:30